how to mix foam concrete

Foamcrete is lightweight concrete designed for. If the mix becomes too stiff to incorporate the beads add additional water as needed.

Expanding Foam Vs Concrete For Fence Posts Handyman S World

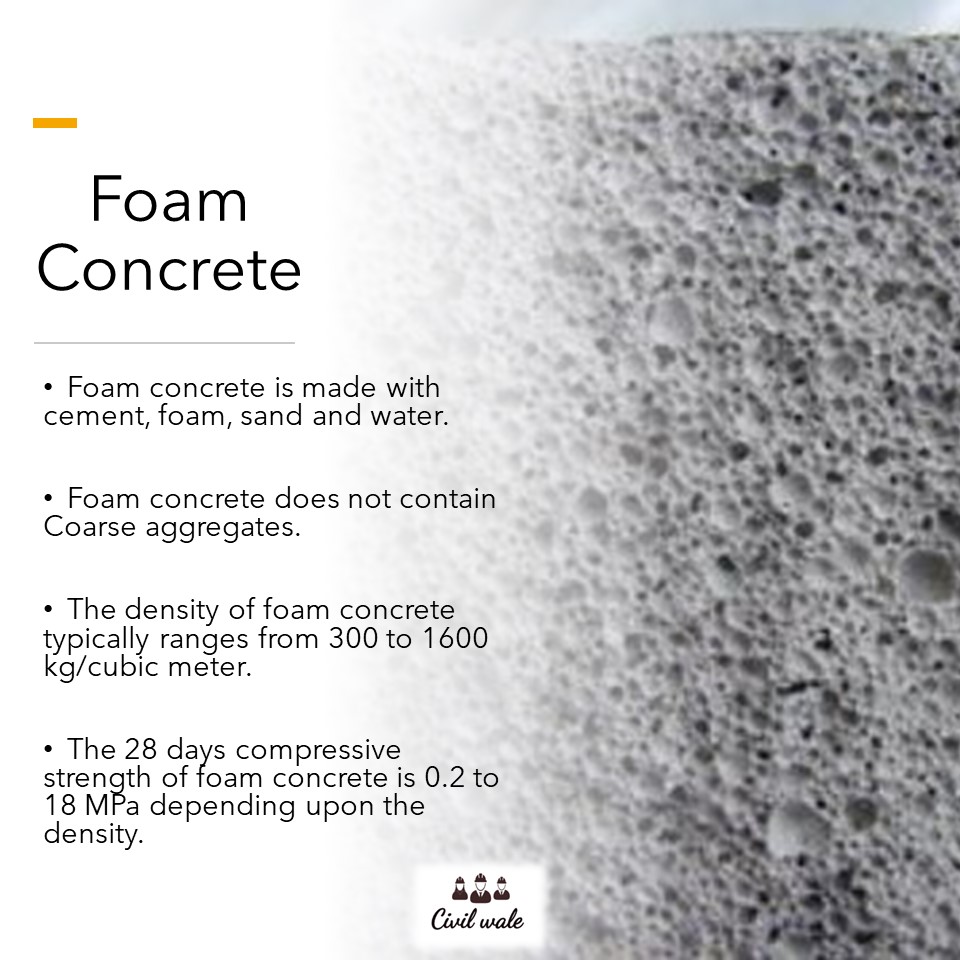

Foam concrete mix itself is made of fine sand cement water and stabilizing foam.

. The process of mixing the concrete is difficult and costs more in terms of labor than that of. You can also mix concrete with pearlite. Disadvantages of Foam Concrete.

A deckfence post and just dont feel like mixing. Pour the dry concrete straight into the hole leaving 3 to 4 inches of space from the top of the hole. It is used for various purposes.

Foamed concrete is a nonstructural void filler that can be dug out with excavators. A short instructional video showing how I have learned to mix and pour aircrete. I wanted to show a more detailed step by step guide with live mixing to real.

Foam concrete is difficulty in finishing project. Content uploaded by Burcin. Foamed concrete is made by mixing foaming agent with mortar in truck mixer.

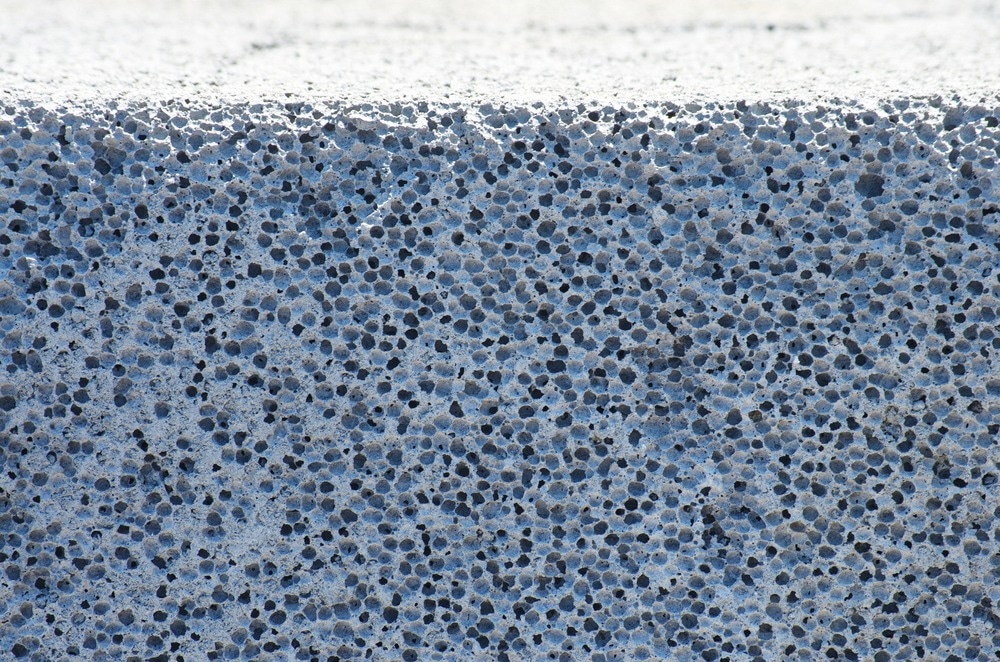

At 50 and 100 kgm 3 foam content the mix containing 100 glass sand had 69 and 81 higher bulk density than the companion mix. The Styrofoam will quickly absorb the water in the mix. How To Mix Foam Concrete.

Hyper Tufa is mixing Portland cement not concrete together with peat moss for a light weight mix makes great pots and bricks for garden borders. Continue adding the Styrofoam taking the time to mix in each bucket after the addition to the cement mixture. The compressive strength of foam concrete is found to be 075 MPa.

It is used for various. What is the mix for foam concrete. Foamed concrete typically consists of a slurry of cement or fly ash and sand and water although some suppliers recommend pure cement.

1 Foam concrete compounds utilising. Kaushal Kishore Materials Engineer Roorkee. The mortar is a mixture of cement sand and water.

Bulk density of foam concrete is obtained to be 250 kgm3 and its heat conductivity to be 0075 WmK. FOAM CONCRETE is a new material that differs from ordinary concrete replacing the inert partially or totally by small air bubbles FOAM. PTH through the grouting machine the foam and concrete are evenly placed into the light steel mesh membrane so that the foam concrete grouting wall has the.

Foam concrete is a versatile building material with a simple production method that is relatively inexpensive compared to autoclave aerated concrete. Foamed concrete also called cellular light weight concrete is produced by the mixing of Portland cement sand including or alone fly ash water and preformed stable foam. If you are going to be setting a deckfence post and just dont feel like mixing concrete check out this fence setting foam from Sika.

Foam Concrete Cast In Situ Work Foam Concrete Also Called Cellular Light Weight Concrete Is Produced By The Mixing Of Cement Sand Water And Preformed Stable Foam The Foam Is By Tijender

Mai Mix Electric Agitator For Foam Mortar And Foam Concrete Production

How Not To Anchor A Fence Post Expanding Foam Fence Post Mix Review

Foam Concrete Ingredients And Its Properties Civil Rack

Styrofoam Concrete 5 Steps With Pictures Instructables

Fine Crumb Rubber An Overview Sciencedirect Topics

Concrete Plants Ms1000 Sircontec

Design And Mix Proportion Of Lightweight Foamed Concrete Lfc Download Table

Precast Aircrete Foam Concrete Panels How To Mix And Pour Youtube

Mix Proportions For Cement Sand Foam Concrete Mixes Download Scientific Diagram

Pdf An Investigation On Foam Concrete With Quarry Dust Replacement For Filler In Mix Design Manish Singh Academia Edu

Concrete Plants Ms1000 Sircontec

Foam Concrete Manufacturing Advantages And Disadvantages Civil Wale

Porous Aggregate Improve Foams In Concrete 3d Printing